Exaktly as you wish!

Our drawing tools

Drawing wires means using a lot of energy to produce a very fine, uniform product that has the same physical properties at every point. This is extremely dependent on the tools used, such as drawing cones, drawing rings and drawing disks – your end product will only ever be perfect if they guarantee the same coefficients of friction and resistance over a long period of use.

Our drawing tools are wear-resistant, offer the best sliding properties and are acid and heat-resistant. Depending on your requirements, we can provide you with drawing tools made of different materials. In addition to all-ceramic tools, we also offer ceramic and metal-coated components.

Coatings

Materials for drawing rings

HCC94 (Chromium oxide)

Color: Black

Base material: Steel

Hardness: 1120 HV10

Layer thickness 0,5 – 0,7 mm

Roughness: Ra 0,2 µm

HCM96 (Tungsten carbide)

Color: Metallic

Base material: Steel

Hardness: 65 – 68 HRC

Layer thickness: 0,6 – 0,8 mm

Roughness: < Ra 0,1 µm

HCZ95 (Zirconium oxide)

Color: Yellow

Hardness: 937 HV10

Roughness: < Ra 0,1 µm

Density: 5,6 – 5,8 g/cm³

HCZ95W (Zirconium oxide)

Color: White

Hardness: 1600 HV0,5

Roughness: < Ra 0,15 µm

Density: 4,0 – 4,2 g/cm³

Products

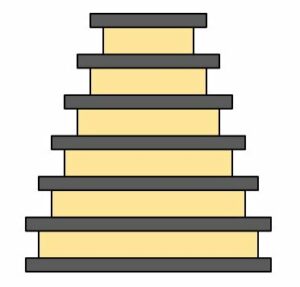

Drawing rollers

Drawing rollers

Drawing tools with ceramic rings. With graduation or uniform diameter.

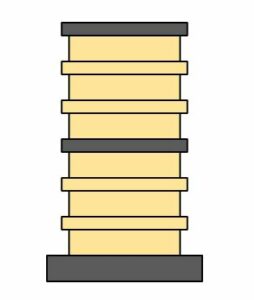

Drawing cones

Coated drawing cones. With graduation or uniform diameter.

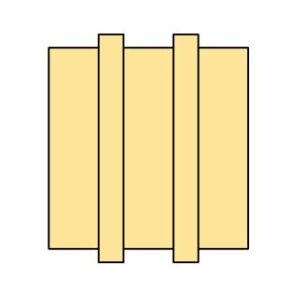

Single drawing rings

Drawing rings for drawing tools

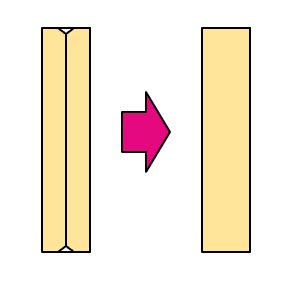

Service: Regrinding

Service: Regrinding

Regrinding of non-coated drawing components

More cost-effective than buying new