Foundry technology

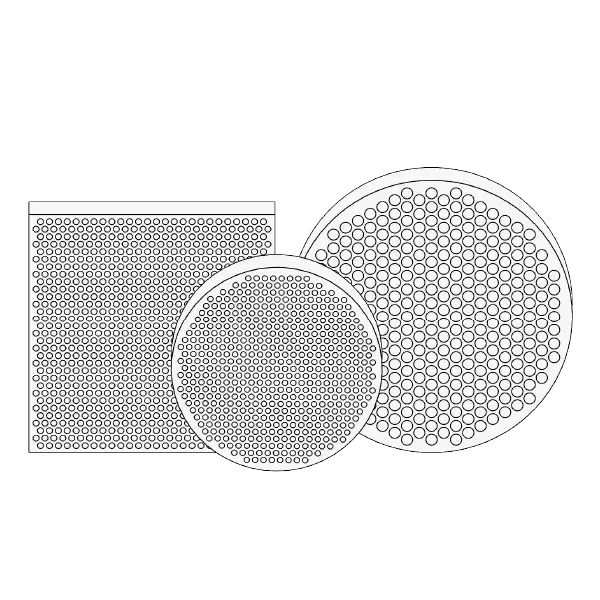

Round hole filter

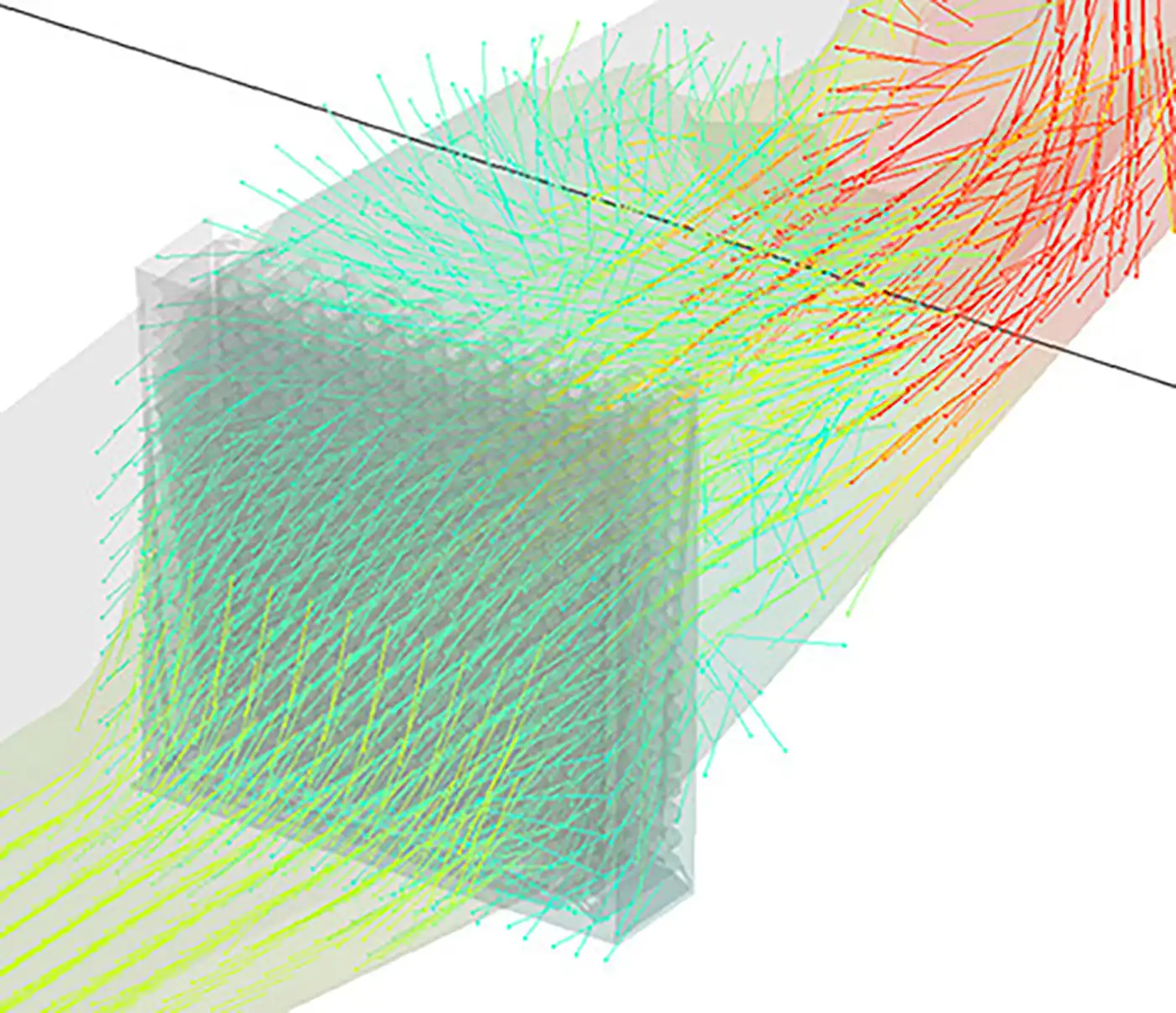

Our pressed ceramic round hole filters are produced using a unique dry pressing process developed in-house and are characterized by the following properties:

- hydraulic properties are more precisely calculable due to the exact geometry

- reproducible mold filling due to consistent flow cross-sections

- precise filter seat due to exact installation dimensions

- a suitable filter geometry can be produced for every application

- filtration results at the highest level are achieved with properly tuned casting systems

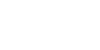

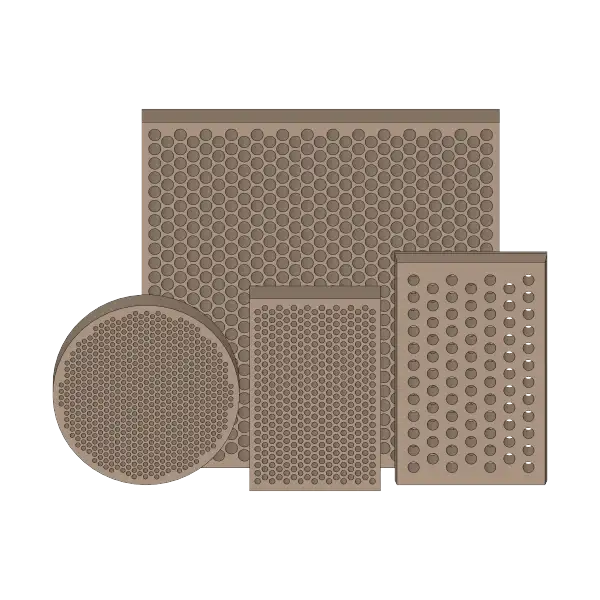

- available in round, square or rectangular shapes

The right filter for every challenge!

GWF round hole filters &

GA strainer cores

Ceramic casting filters for iron casting and non-ferrous metals

- THE standard filter for almost all applications

- Robust in handling without crumbling

- Precise contours for automatic insertion

Hipercast®

Filter

High-temperature resistant, extra-robust filter for the highest demands in large-scale and steel casting

- Casting temperatures up to 1750°C

- Flow rates up to 15 t in gray cast iron and up to 9 t per filter in ductile iron

- high savings potential for recycled material and sand

Hipercast®-Plus

Filter

Maximum casting performance and savings in combination with casting systems developed by us

Exothermic EXHOF-L feeders

To meet our commitment to environmentally conscious action, we offer our customers highly exothermic feeders. In addition to a low-fluorine and low-sulfur composition, our feeders are characterized by significantly reduced smoke emissions due to the modern, inorganic binder system.

- environmentally friendly, low-smoke formulation

- also available with low fluorine or fluorine-free on request

- available in all sizes and shapes

- highest performance with consistent quality

- transparent and traceable documentation of all feeder batches

The right feeder for every application!

L-Series

- low overall height

- highest yield

- dimensionally stable & accurate

- shortest heating times, high firing temperatures and long holding times

Contour and special feeders

- Individual in-house development according to customer requirements

Prototypes

- Prototypes available within 4-5 days

- shortest development and project phases in the foundry

- no tooling costs

SiC chill molds

Our chill molds are always used when uniform structural properties are required in highly stressed cast part areas where the necessary heat must be moderately extracted to avoid casting degeneration. This is achieved through the composition of the mass in combination with the manufacturing technology used.

- prevent undesirable hard edge zones

- reduce machining costs

- promote homogeneous microstructure formation in the effective area

- available in various sizes and shapes

- reusable